Maximize Productivity and Quality with Scalable Industrial IoT Solutions

Create efficient, flexible, and reliable industrial IoT solutions and SCADA systems that scale across devices, verticals, and functions.

One Framework for Any Device

Join the leading players of Industry 4.0 in using Qt for high-performance SCADA, DCS, PLC, and CNC systems.

High-Accuracy Factory Monitoring

Leverage fast and accurate real-time usage intelligence, for data-driven decision-making.

Remote Accessibility and Control

Support for connectivity with multiple platforms and devices for full control over factory operations.

Quality, Reliability, and Security

Efficiently create intuitive industrial software meeting quality regulation standards.

Comprehensive Tools for Industrial Software

From design to development and testing, deliver quality in less time with tools that speak the same language.

Trusted by Leaders in Industrial Automation

Your One-Stop Partner for Industrial Software

Maximize efficiency and cost savings with a single end-to-end technology for your entire IoT factory—covering design, development, and quality assurance across a spectrum of devices ranging from low-end microcontrollers to high-end MPUs, spanning from embedded to desktop and mobile.

Be it the SCADA systems in your control room, the PLCs controlling the factory machines, or the rugged tablets used by operators, Qt cross-platform capabilities enable seamless reuse of software components on any devices. This not only enhances quality and user experience but also contributes to cost efficiency and faster time-to-market. In the context of Industry 4.0, where connected devices communicate, exchange data, and automate processes, Qt serves as a comprehensive middleware solution. With APIs for networking, threading, database access, location, and more, Qt empowers you to build a fully connected factory from a single codebase.

.png?width=850&name=QT_IA_still_03_cropped%20(1).png)

High-Accuracy and High-Performance Tooling for Unparalleled Industrial IoT Applications

Build fast and accurate real-time industrial applications capable of efficiently handling multiple concurrent processes, huge data loads, and state-of-the-art graphics.

Industrial software applications need real-time control over complex decentralized processes involving large amounts of data from remote sensors and advanced 2D and 3D graphics. Qt’s architecture is designed with performance in mind and optimized for real-time applications, with tooling for multi-thread execution of concurrent processes, on-demand behavior, and memory management, to mention only a few. Qt’s optimized data structures enable handling large datasets and real-time graphics with unparalleled performance on embedded systems.

Empower Your Factory Operations by Unlocking Accessibility and Control

Tame the complexity of industrial IoT automation by means of flexible, easily customizable SCADA systems enabling real-time control of any machine from any location.

For the implementation of advanced SCADA systems, the Qt framework’s connectivity tooling and real-time graphics capabilities deliver intuitive, responsive, and effective UI applications enabling data-driven decision-making in the industrial process. You can achieve the highest degree of automation and easy portability across devices, working environments, and functions with Qt's broad out-of-the-box support for connectivity with multiple platforms and devices (Qt Serial Bus), remote desktop accessibility (Qt WebAssembly), cloud and edge connectivity (Qt HTTP Server), and machine-to-machine interaction (Qt Serial Bus, Qt MQTT, Qt OPC UA, Qt GRPC).

.png?width=850&name=QT_IA_still_07_cropped%20(1).png)

Meet the Industry Standard of Quality, Safety, and Security

Create dependable Industrial IoT devices that can be operated in full safety and security, with or without wireless connectivity, through any type of input/output interface—including physical knobs and touch screens.

With its transparent, well-documented code development practices and continuous integration and testing process, the Qt code meets the highest requirements of reliability, resiliency, and functional safety—including possible adherence to the Safety Integrity Levels defined in IEC61508 or DO-178C.

In terms of tooling, the Axivion code analyzer helps you comply with coding guidelines and safety requirements. The Qt Safe Renderer ensures that safety-critical information (e.g., alarms) is promptly displayed under any circumstances. Qt LTS releases deliver stable APIs, ensuring long-lasting competitiveness in the market.

Upgrade Your SCADA System with Advanced 2D and 3D Real-time Graphics

Visualize your industrial data and processes, control the status of your equipment, detect trends and patterns, identify optimization strategies by exploiting real-time 2D and 3D rendering capabilities for enhancing business intelligence, VR and AR simulation, digital twin technology, remote operation, and more.

Qt state-of-the-art real-time graphics capabilities enable the visualization of complex data in the form of 2D charts and graphs to quickly identify patterns and trends, but also the creation of immersive 3D experiences for the implementation of digital twins for testing and optimizing processes, of VR environments for remote maintenance and training, and of CAD models for accurate visualization and analysis.

Explore Innovation in Industrial Automation

with Our Demo

Customer Stories Written with Qt

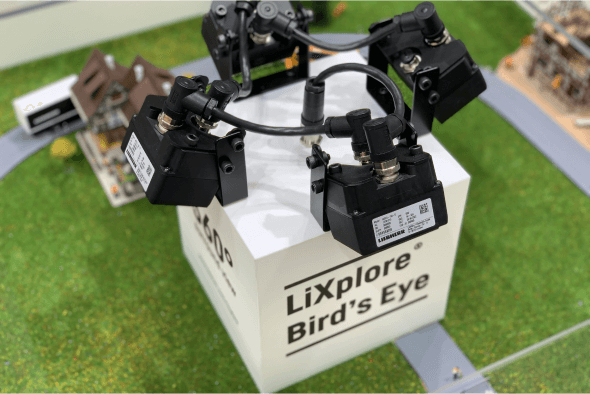

Liebherr-Electronics and Drives GmbH offers mobile machine operators detailed views of their working environment, with strong technical support from Qt and responsive contacts.

The ABB Group uses Squish GUI Tester in protection relay development to ensure quality and safety, with scripts built by modeling the UI structure rather than recording.

.webp)

Novatron uses the Qt framework in heavy-duty equipment control systems for seamless data flow and sensor-based visualizations, emphasizing the need for reliable systems in their work.

.png)

The project aimed to reduce machinery cabin displays by creating an app-based product that integrates multiple applications into one display, with QML offering impressive ease-of-use and efficiency.

lue Ctrl AS develops marine automation systems using their X-CONNECT® platform, built entirely on Qt, allowing efficient configuration of vessel operations, handling both backend and GUI aspects.

Precision Planting used Qt for their 20|20 GUI system, offering farmers real-time equipment insights during planting and harvest, opting for Qt over switching to JavaScript or HTML.

BOMAG uses Qt for their myCOCKPIT HMI, enabling efficient operation of complex systems with integrated camera displays, process parameters, and system status.

More on UX, Product Planning, and Industrial Applications

Adapt or Fall Behind: Scalable Solutions Reshaping Manufacturing

From code reusability to decentralized control systems, scalable solutions are not just reshaping manufacturing automation; they're revolutionizing it.

Read ArticleThe Future Landscape of Industrial Automation

World-leading industrial manufacturers leverage connectivity, advanced 2D and 3D graphics, and AI to increase performance, minimize downtime, and boost competitiveness.

Designing for Efficiency: UX Solutions for Industrial Automation

Spurred by the implementation of AI, robotics, and other technologies, the global industrial automation market is projected to reach USD 265 billion by 2025. UX is one solution to the challenges presented by this scramble to automate.

The Critical Role of GUI Design for Safety, Efficiency, and Interoperability

Discover the importance of GUI design in industrial automation for safety, efficiency, and interoperability.

UI Design: Functionality, Tooling, and Workflow

Learn about the capability of a full-fledged UI Framework and simplify your software development process.

Read eBookQt in Industrial Vehicles

Optimize your production processes with intelligent digital solutions for Commercial, Construction, Naval, and Agricultural Vehicles by developing connected, integrated machines operable with ease and security.

Learn MoreCreate Your Next Industrial Automation Project with Qt

Take advantage of an end-to-end solution for industrial product design, development, quality assurance, and deployment.

The Qt framework allows you to build your Industrial IoT applications in conjunction with AI, VR, and cloud computing, enabling advanced business intelligence, new insights into industrial processes, and data-driven decisions that lead your business to a new level of efficiency, productivity, and profitability.