Developing And Manufacturing Components With Quality And Reliability

Liebherr sees itself as a pioneer. Based on this attitude, the nearly 50,000 employees play a decisive role in shaping technological progress in numerous industries and are already dedicating themselves today to the challenges that customers will face tomorrow.

The management of the Liebherr Group is still in the hands of the Liebherr family.

1949

Hans Liebherr invents tower crane

50k

Liebherr Group employees

13

Product segments

Solution Highlights Enabled with Qt

Improved safety for operators because of better visualization of the surrounding area and potential obstacles around machines/vehicles.

Scalable UI approach for different screen sizes and orientations.

Easy to use UI/UX for operators.

“On a technical level, cooperation and support from Qt worked great. My contacts were always available for questions and comments.”

Michael Kipp, Software Engineer, Product Line Sensors, Liebherr-Electronics and Drives Gmb

Liebherr-Electronics and Drives GmbH bauma exhibition video

Watch the video to see Liebherr's team demonstrate their digital surround view system in action!

A long tradition in manufacturing quality

With its history and roots going as far back as 1949, Liebherr has been a self-made pioneer and major player in the manufacturing of construction machinery ever since.

Today, Liebherr-Electronics and Drives GmbH, based in Lindau and Biberach, Germany, employs about a thousand dedicated people who develop and manufacture customer-specific electronic solutions. In Lindau, Liebherr develops and manufactures high-quality electronic components that are used throughout in the group's various companies, and in the industries of long-life electronics and aerospace. The electronic components hold significant importance in the variety of Liebherr products, hence, external customers from a variety of different fields also rely on Liebherr's durable solutions and their robust construction.

“When developing the system, it was important to us that we offer our customers the greatest possible scope for individualizing the user interface (graphical user interface).”

Alexander Bertsch, Head of Product Line Sensors, Liebherr-Electronics and Drives GmbH

Safety and higher performance through 360-degree visualization

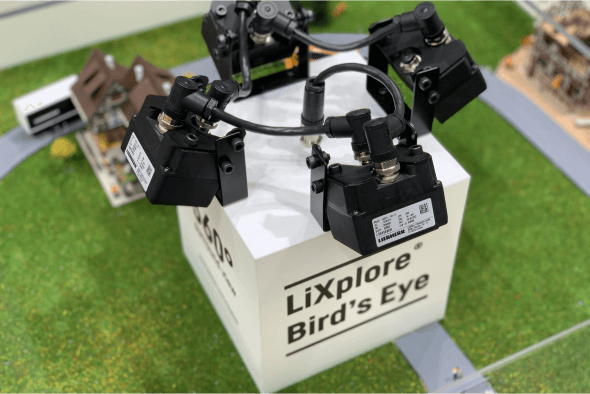

Liebherr-Electronics and Drives GmbH requested the development of two applications for visualizing streams from the connected digital cameras: a Bird's eye application, and a CMS (camera-monitor system) application. These applications provide operators of a mobile machine with detailed views of the working environment.

The Bird's Eye View application shows a 360-degree view of the connected cameras. The CMS application displays one or more streams from connected cameras. Both systems support the driver by displaying the surroundings in detail, thus increasing comfort and work safety.

How the project was completed with Qt:

- Creation of UI design and implementation of UI using Qt/QML

- Integration of 3rd party software into system and controlling of cameras

- Performance optimization for the embedded system

"The Qt software environment is designed in such a way that we can also quickly and flexibly map future customer requirements with appropriate features”, says Alexander Bertsch, Head of Product Line Sensors at Liebherr-Electronics and Drives GmbH.

Try Qt for Your Embedded DevicesHave a brilliant idea, but don't know how to exeQte it? Get in touch and we'll help you out.