BUILT WITH Qt

Kyungwoo Systech

Partnering with Qt Group for a proactive response to market changes with innovative solutions.

Driving the Future of Software Defined Off-Highway Vehicles

50%

Reduction in Development Cycles

Kyungwoo Systech, a 25-year industry leader in ICT-based automotive electronics solutions for construction and industrial vehicles—including HD Hyundai, Doosan Bobcat Korea, and Clark—uses Qt Framework for their KLION™ product line for Software Defined Off-highway Vehicle (SdoV).

Qt helps Kyungwoo Systech swiftly adapt to the electrification and automation of industrial equipment while continuously enhancing user experience.

Learn how Qt Framework and QML support cross-platform development, allowing Kyungwoo Systech to shorten development times and optimize development resources.

The digital transformation of industrial vehicles is no longer optional but essential. Qt Group has been a powerful partner in helping us revolutionize the user experience and build an efficient development environment.

Sungjin Cho, Director of the Automotive & Industrial Business Unit, Kyungwoo Systech

Qt Solution Highlights

Unified cross-platform development across Microprocessor (MPUs) and Microcontroller (MCUs) units.

A single framework to work across devices, with the ability to reuse work done for one type of device on the other.

50 % reduction in development cycles allowing faster product launch.

Dynamic UI/UX with QML for engaging user experiences, even on low-spec hardware.

Lifecycle-aware design for efficient software integration and operational efficiency.

Scalable and secure platform for continuous digital transformation.

Adapting to a Fast-Evolving Market

Mirroring trends in the large automotive sector, industrial vehicles are rapidly evolving into Software Defined Off-Highway Vehicles (SdoVs). In producing solutions for this market, Kyungwoo Systech needs to provide seamless integration of advanced connectivity, AI, and dynamic user interfaces—all while ensuring robust safety and efficiency standards.

To achieve this, the company first had to unify a fragmented development environment, where managing separate development streams for different operating systems and varying display sizes led to inefficiencies. Each model required distinct resources, resulting in inconsistent user experiences and prolonged development cycles.

Additionally, Kyungwoo Systech’s solutions for SdoVs range from sophisticated Vision AI-based safety systems to simpler hydraulic control units. The need to integrate hardware and software across different platforms posed a significant challenge. Finally, the company had to reduce time-to-market while taking care that each product could adapt to future technological advancements.

After reviewing various development environments, including development tools provided by silicon suppliers and proprietary tools developed for specific functions, Kyungwoo Systech turned to Qt.

We were particularly impressed with Qt Framework’s ability to deliver consistent quality and performance across various hardware platforms.

Sungjin Cho, Director of the Automotive & Industrial Business Unit, Kyungwoo Systech

A Unified, Next-Generation Solution

To accelerate the digital transformation, Kyungwoo Systech partnered with Qt Group to reimagine its development approach. Using a single, cross-platform framework, they developed the KLION™ product line for the SdoV market.

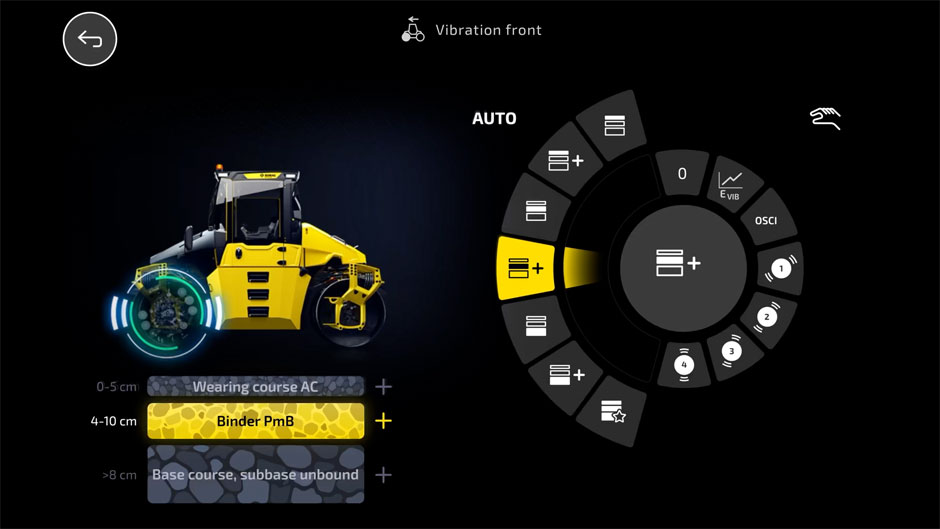

The AI-connected KLION™ Alpha-series Cluster was developed using Qt Framework while the KLION™ Zeta-series Cluster was built using Qt for MCUs.

We chose Qt because it supports cross-platform development across both MPUs and MCUs, enabling the efficient unification of development resources. Says Sungjin Cho.

The unified framework provided by Qt eliminates the inefficiencies of maintaining separate development environments for various operating systems. This consolidation has reduced the overall development time by over 50%, enabling Kyungwoo Systech to bring innovative solutions to market faster.

Using QML allowed us to shorten the development timeline and rapidly implement diverse UI animations in the clusters, providing a more innovative user experience.

Delivering Real World Impact

The adoption of Qt transformed Kyungwoo Systech’s operations.

A unified development approach ensures reliable performance and a refined user experience across all hardware configurations, while also driving significant cost savings and improving time efficiencies. Says Sungjin Cho

Streamlined software integration and lifecycle-aware design translate into improved cost-effectiveness and long-term value, driving continuous innovation in safety and control systems.

The benefits go beyond simple cost savings as we ultimately saw great enhancements in customer satisfaction.

With development cycles slashed by more than half, Kyungwoo Systech can respond quickly to market demands and stay ahead in the digital transformation of industrial vehicles by rapidly iterating and launching products. The flexibility of Qt Framework enables the adoption of future-ready technologies, ensuring Kyungwoo Systech’s solutions remain at the forefront of the SdoV digital transformation.

Fueled by the success of the collaboration so far, Kyungwoo Systech plans to adopt Qt Group’s Coco for Code Coverage to enhance software quality through code coverage analysis and further strengthen its market competitiveness.

With this partnership with Qt Group, Kyungwoo Systech will continue to proactively respond to market changes and provide even more innovative solutions to its customers.

Sungjin Cho, Director of the Automotive & Industrial Business Unit, Kyungwoo Systech

Alpha-Series AI-Connected Cluster to Enable Softwared Defined Off-Highway Vehicle

About KyungWoo Systech

Kyungwoo Systech, Inc. has been a leader in developing and providing Information & Communication Technology-based automotive electronics solutions for construction equipment and industrial vehicles for 25 years. We are a trusted one-stop solution partner committed to developing, designing, and manufacturing innovative, high-quality automotive and safety solutions.

KLION™ drives the digital transformation of automotive and industrial vehicles, built on our extensive expertise in electronics system development, design, and market domain knowledge. KLION™ is at the forefront of transforming machinery into 'living' entities that continuously evolve by integrating advanced Software, Connectivity, and AI technologies.

Oh, There's More

Precision Planting | Built with Qt

Precision Planting is a leading provider of agriculture technologies that upgrade a farmer’s existing planter, air seeder, drill, sprayer, liquid fert...

Read more

Blue Ctrl | Built with Qt

Blue Ctrl AS develops marine automation systems based on its comprehensive, state-of-the-art X-CONNECT® automation platform. Built entirely on the Qt ...

Read more