The Evolution of Industrial Vehicles—Powered by Qt

Qt Group maintains a constant commitment to developing cutting-edge functionality that enhances safety, efficiency, and productivity in the next generation of industrial vehicles.

See our demos to learn what type of functionality you can access with Qt.

Enhanced Safety and Productivity

With broad out-of-the-box support for connectivity, remote access, and M2M interaction, Qt lets you control your machines from any location.

Real-time communication between machines in the field and remote workstations lets you remove operators from hazardous or straining working conditions.

Real-time data monitoring and predictive maintenance enhance productivity by reducing downtime, detect peaks and idle time in equipment use, and optimize resource usage.

Remote Operations via Digital Twin

Qt's state-of-the-art 3D graphics bring lifelike situations to any screen, enabling a 360° remote visualization of your vehicle in its environment.

High-definition digital twins deliver sharp control over your physical machine, reducing the risk of accidents by removing blind spots and providing an all-round visual awareness.

Optimized for embedded systems and low-end hardware (incl. MCUs), Qt advanced graphics deliver intuitive visualizations of complex information for enhanced machine usability.

Smooth and Precise Machine Control

Qt is designed with performance at its core, and its architecture is optimized for real-time applications that need to handle large datasets without lags.

You can monitor and control your machines with the same response time as sitting in the cab. Actionable machine performance data can be accessed from mobile, tablet, or desktop device—on or off the jobsite.

Qt’s optimized data structures let you analyze and display large datasets with unparalleled performance and quality for easy integration of AI optimization in your production process.

Demo

Advanced Graphics for Digital Twin Tech

With Qt Quick 3D you can build immersive real-time 3D experiences to monitor and control your equipment on the field.

- State-of-the-art graphics capabilities for photorealistic real-time rendering

- Seamless interaction of 2D and 3D elements within one framework

- Graphics acceleration and optimization for embedded systems

Learn how to port Advanced 3D graphics into your machines and remote control stations with our Excavator Digital Twin demo

See how you can leverage Qt Group's products and end-to-end tooling to deliver production-grade software for the Mining Industry

Demo

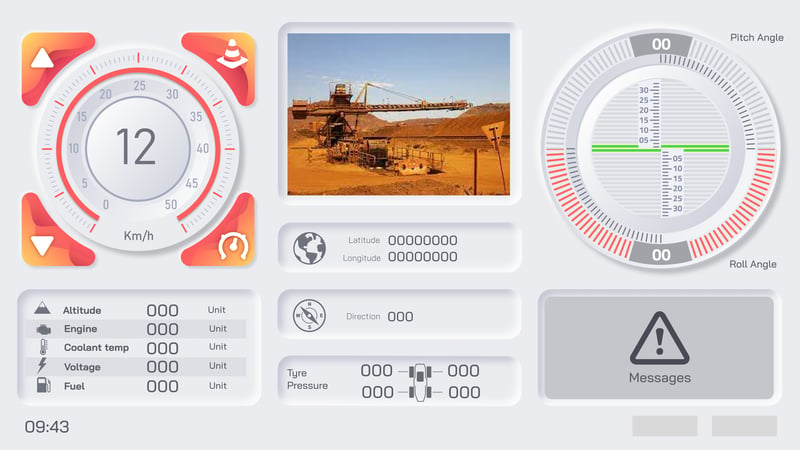

High-Performance HMIs for Real-Time Control

With Qt Quick & QML, you can build modern, highly responsive, dynamic HMIs that readily support your operators in clear, non-invasive ways.- Enhanced performance via optimized rendering and hardware acceleration

- Instant notifications across devices, sites, facilities

- Remote data access and control

Demo

Scalability across Platforms and Devices

Qt lets you seamlessly port high-performance HMIs to desktop, mobile, and embedded devices—including microcontrollers.

- Code development on a single codebase that can be deployed to any platform, including MCUs

- Ability to manage different devices under a single comprehensive and flexible framework

- Ability to reduce cost and avoid risks by resorting to a wide range of platforms

Build light-weight HMIs for MCU devices with all your operators need to control a forklift, including advanced graphics, navigation, camera feed, and more

More Resources

Qt for Industrial Vehicles

Optimize your production processes with intelligent digital solutions for Commercial, Construction, Naval, and Agricultural Vehicles.

Supported Hardware and Operating Systems

Check all Qt-supported platforms and readily available BSP.

Evolving the Workforce: User-Centric Design in Industrial Vehicles

Transforming industrial vehicle interactions with user-centric design to enhance productivity. Prioritizing intuitive interfaces and collaboration reshapes the workforce landscape.

Qt Professional Services

Unlock Qt's full potential by leveraging the technical expertise and industrial experience of the core Qt developers.

Explore Qt Demos

From immersive 3D experiences to concrete industrial applications, our demos showcase the art of possible with Qt Group's technologies.