SUCCESS STORIES

1+ Billion Devices and Applications Powered by Qt

Featured Success Stories

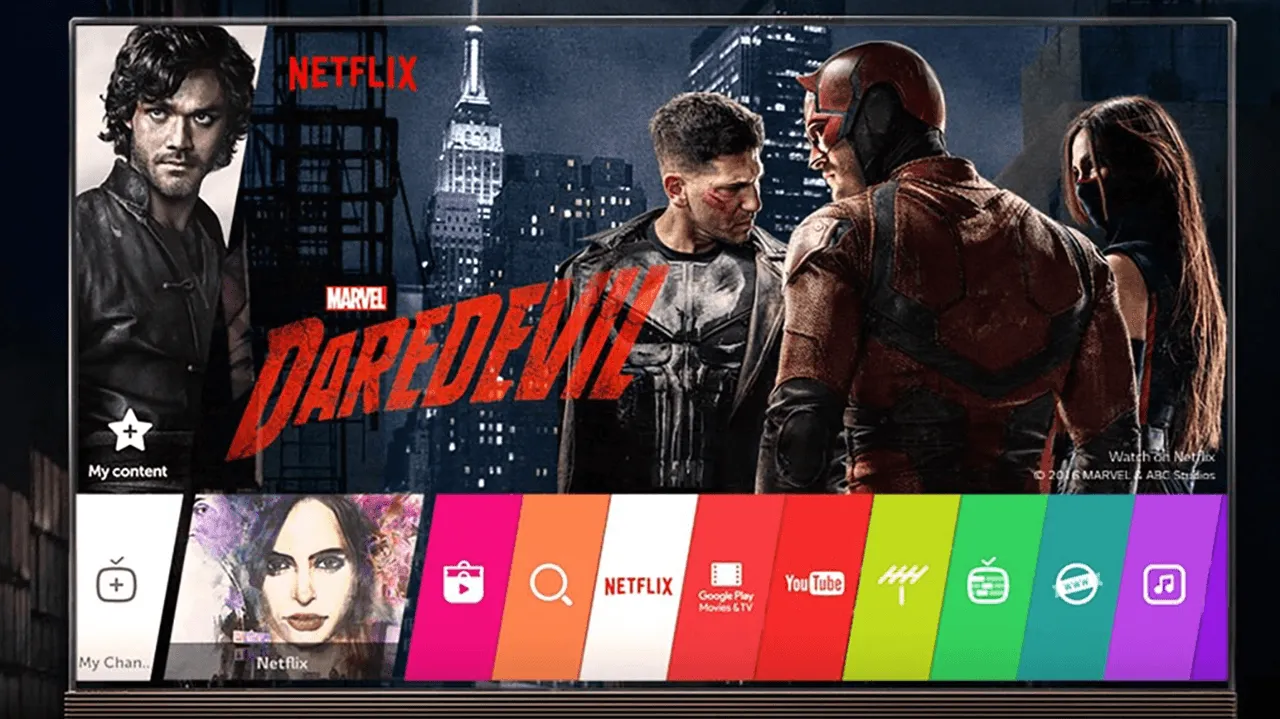

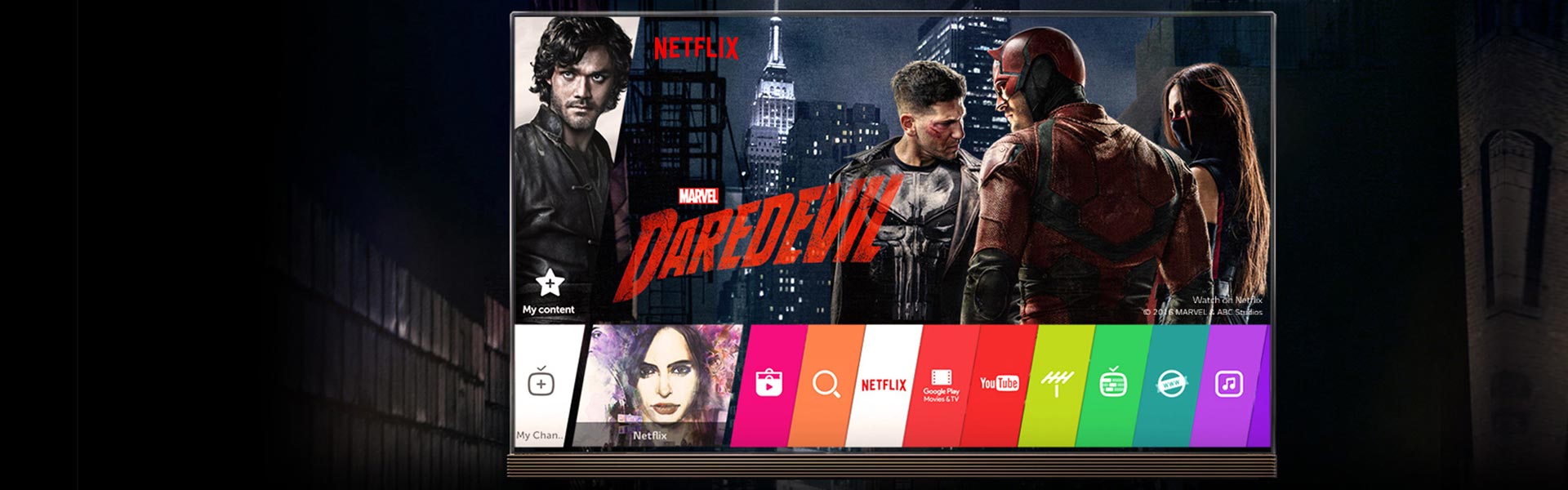

LG chose Qt for its faster performance and lower memory usage, essential for customizing webOS and delivering a superior user experience.

.webp)

With Qt, Dräger were able to deploy their state-of-the-art UIs on resource-constrained hardware without compromising the performance.

.webp)

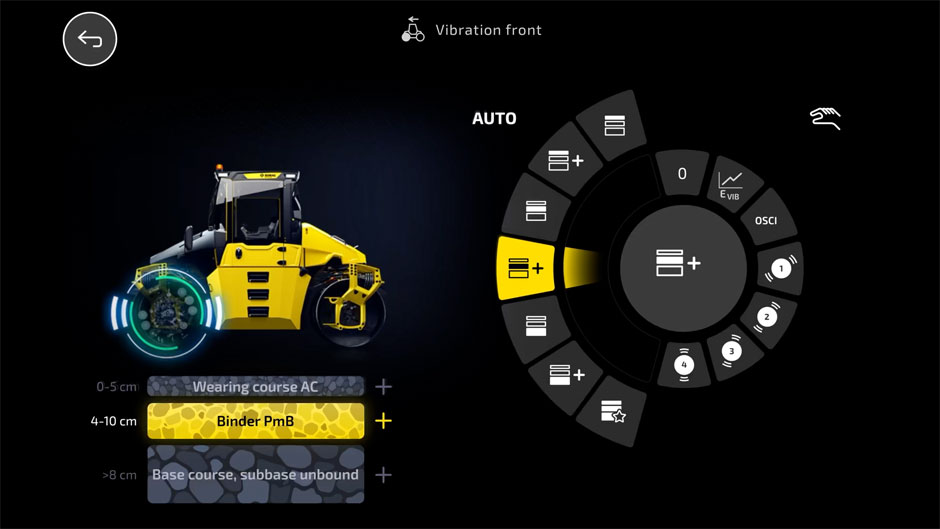

Liebherr-Electronics and Drives GmbH offers mobile machine operators detailed views of their working environment, with strong technical support from Qt and responsive contacts.

%20(1)%20(1).webp)

Upgrading to Qt 6 to support MB.OS across cars, leveraging cross-platform development, and shortening time-to-market.

.webp)

B/S/H utilized Qt to create reusable atomic UI components, enabling a consistent and optimal UX across different devices and projects.

.webp)

Qt equips Fresenius Kabi with efficient tools for designing medical devices and automating extensive testing to set new industry standards.

%20(1)%20(1).webp)

Ultifi platform utilizes Qt for scalable, efficient software updates and brand differentiation.

Discover All Success Stories

Volven | Built with Qt

Volven is a Norwegian fintech company with over 25 years of experience in traditional finance. The company aims to create a high-performing crypto tra...

Read more

Foilone | Built with Qt

Foilone turned to Qt Accelerate for a ready-made, easily deployable product offering rapid integration with the boat's infrastructure and a wide range...

Read more

CLEAN MOTION | Built with Qt

CLEAN MOTION chose Qt Accelerate to swiftly implement an HMI solution for their EVIG last-mile delivery vehicle, achieving rapid integration and exten...

Read more

Roland | Built with Qt

Learn how Roland leverages Qt tools to create best-in-class products while decreasing development effort and verification time.

Read more

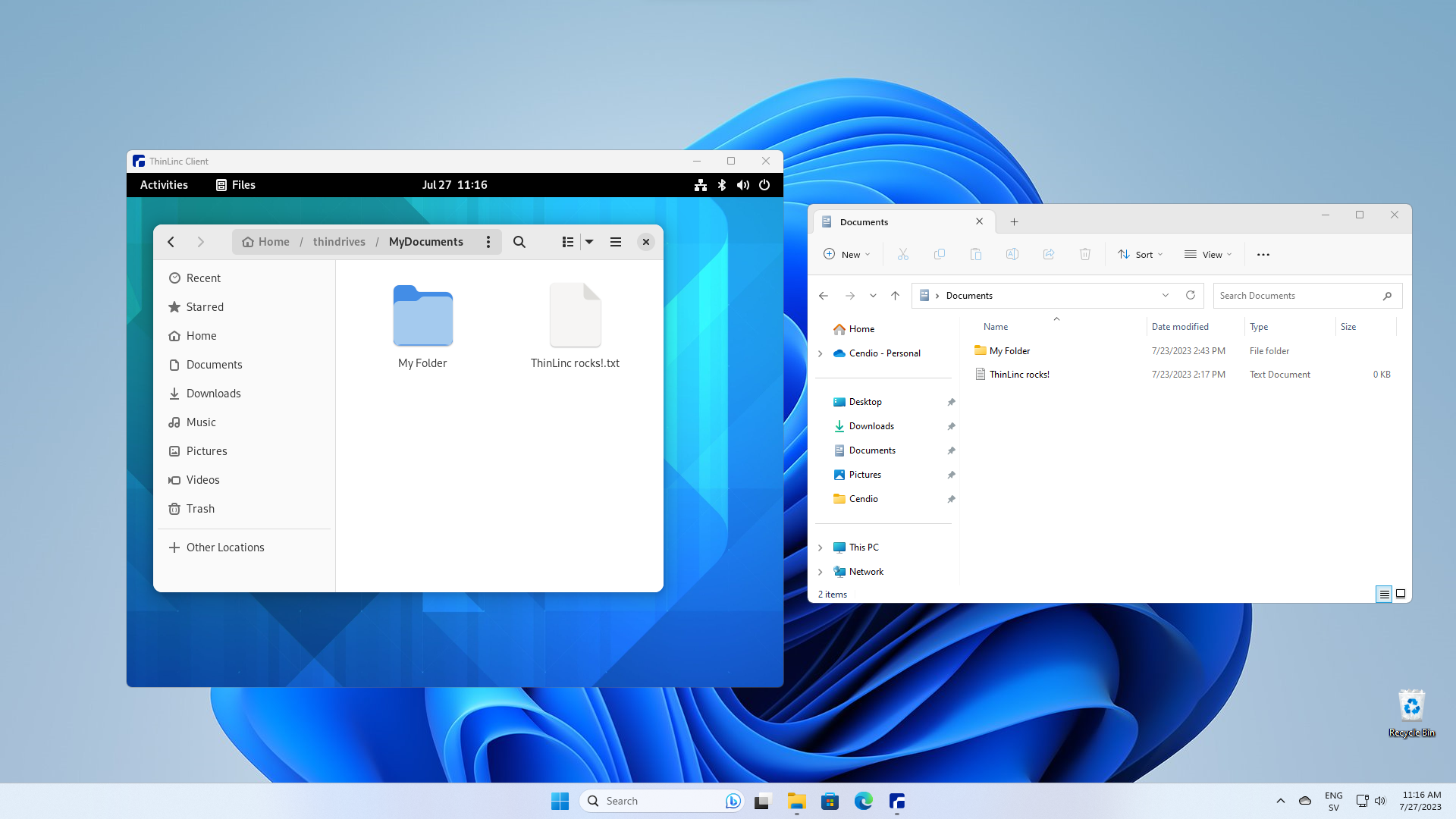

ThinLinc | Built with Qt

ThinLinc has undergone a major architectural upgrade, leveraging the Qt framework to bring in state-of-the-art functionality and look-and-feel.

Read more

Precision Planting | Built with Qt

Precision Planting is a leading provider of agriculture technologies that upgrade a farmer’s existing planter, air seeder, drill, sprayer, liquid fert...

Read more

Blue Ctrl | Built with Qt

Blue Ctrl AS develops marine automation systems based on its comprehensive, state-of-the-art X-CONNECT® automation platform. Built entirely on the Qt ...

Read more

USEN-ALMEX | Built with Qt

USEN-ALMEX uses Qt to develop "Mynatouch," a card reader with face recognition that supports online qualification verification.

Read more

Hasselblad - Built with Qt

A recent example of Hasselblad's technical leadership is the new medium format camera X2D 100C, which uses Qt on all its displays, including Qt for MC...

Read more

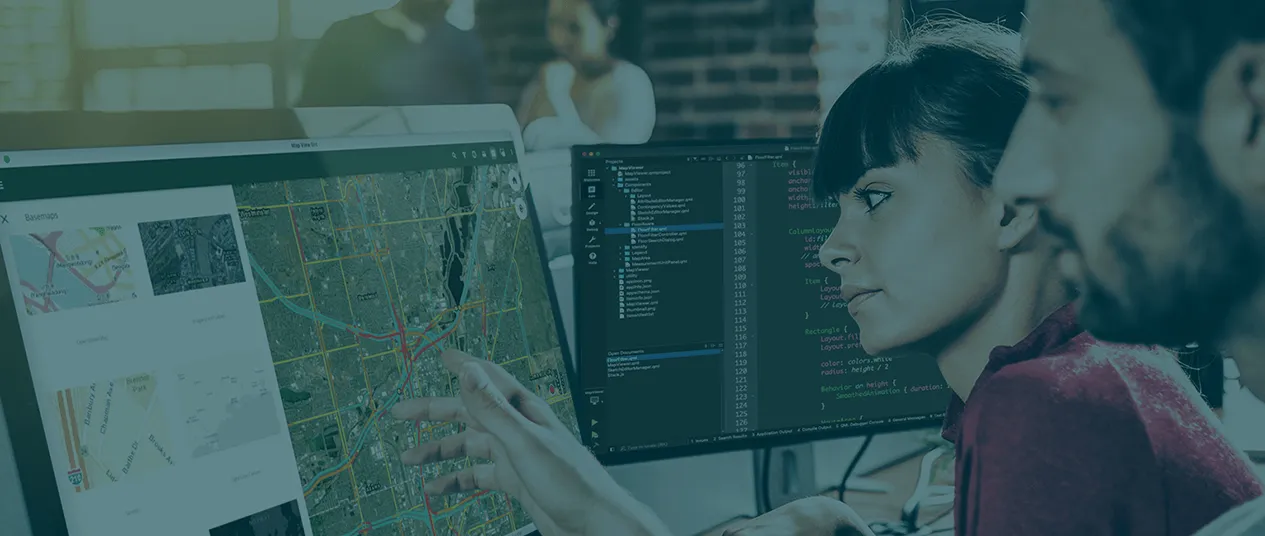

ArcGIS Maps SDK for Qt | Built with Qt

Esri is the global market leader in Geographic Information System (GIS) software, location intelligence, and mapping. Read their customer story here.

Read more

Gruppo Cimbali | Built with Qt

The Qt framework powers La Cimbali's Model S digital display.

Read more.webp)

S3 Fuzion's Xelorate | Built with Qt

Stop searching, start finding with S3 Fuzion's Xelorate.

Read more

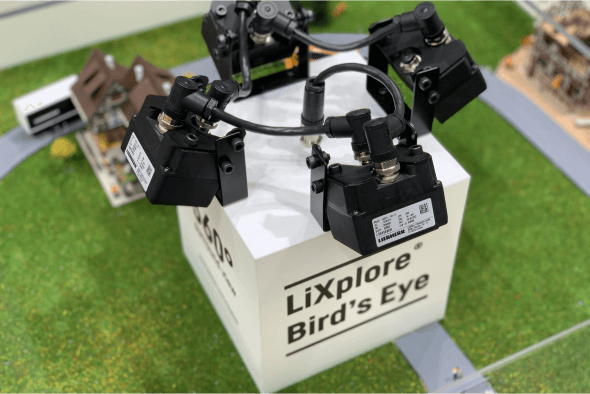

Liebherr-Electronics and Drives GmbH - Built with Qt

Qt's framework and components power Liebherr-Elektronik GmbH's Bird's eye and CMS (camera-monitor system) applications.

Read more

RGNT Motorcycles - Built with Qt

RGNT chose Qt as it offers so many effective out-of-the-box solutions for these purposes. In less than a year, a small team of developers was able to ...

Read more

Bricsys | Built with Qt

Bricsys is a global provider of the BricsCAD® brand of engineering design software. Learn about their journey and successes using Qt.

Read more

EM Microelectronic - Built with Qt

EM Microelectronic (Swatch Group) partners with Qt Group to leverage the advanced UI capabilities offered by the Qt framework for the creation of thei...

Read more

AirServer – Universal Screen Mirroring Receiver Built with Qt

AirServer is a cross-platform screen mirroring solution that allows you to project from any Apple, Google or Microsoft device to any TV, monitor or pr...

Read more

AMD – Graphics software

Computing and graphics powerhouse AMD uses Qt in development of its Radeon Software Crimson Edition graphics package.

Read more

BEP Marine – Marine Automation Systems

BEP Marine chooses Qt to empower agile development and create user interfaces for their CZone system.

Read more

LG – Electronic Smart TVs

LG’s innovative technologies, unique products, and cutting-edge designs are built with Qt.x

Read more

Medec – Anesthesia & Critical Care Medical Devices

Qt-based anesthesia & critical care medical devices offer superior user experiences with patient safety in focus.

Read more

Rimac Automobili – Car Infotainment System

Discover how Rimac Automobili used Qt to build a premium car HMI. Automotive software development and hardware development is best with Qt.

Read more

Clarius – Ultra-portable ultrasound scanners Built with Qt

Learn about the pocket sized range of ultrasound scanners shaking up the medical industry, and why they were built with Qt.

Read more

Dubler – Vochlea's real-time voice-to-midi controller Built with Qt

Dubler is a software for musicians. It tracks the pitch, envelope, and timbre of your voice to let you vocally control effects, expression & pitch...

Read more

Eykona – 3D Wound Imaging

Qt-based anesthesia & critical care medical devices offer superior user experiences with patient safety in focus.

Read more

Firstbeat Sports built with Qt

Firstbeat Sports provides holistic physiological performance insights to make informed coaching decisions and maximize the team's performance potentia...

Read more

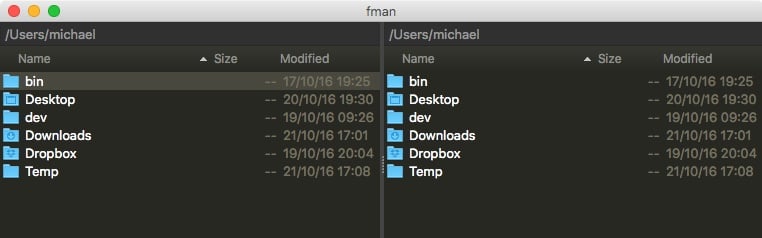

fman – The Cross-Platform, Dual-Pane File Manager that Makes You Faster!

fman – the cross-platform, dual-pane file manager that makes you faster, built with Qt and Python!

Read more

Formlabs – Advanced Desktop 3D Printers

With Qt, Formlabs delivers intuitive and connected 3D printing experience.

Read more

Framery's Happier & More Efficient Workplaces

Qt empowers Framery, the pioneer and the world’s leading manufacturer of soundproof private spaces for solving noise and privacy issues in open office...

Read more

GLP Systems – A Breakthrough Development in Laboratory Automation

GLP Systems chose Qt because of the comprehensive & highly intuitive APIs, modularized C++ libraries, declarative programming technology, and tool...

Read more

HeartWorks — Training doctors to diagnose heart conditions with world's most accurate 3D virtual heart.

HeartWorks is an ultrasound simulator that uses a computer, a mannequin & 2 ultrasound probes used for teaching cardiac anatomy & echocardiogr...

Read more

Hiri – Enterprise E-mail

Hiri, the best email client for Managers on Windows, Mac, and Linux is built with Qt.

Read more

News: Koenigsegg – Record-Breaking Supercars Built with Qt

Koenigsegg used Qt's complete toolkit and Professional Services to create the ultimate high-performing automotive software.

Read more

Gamry Instruments — Market Leader in Electrochemical Instrumentation Teams up with Qt Service Engineers

Market Leader in Electrochemical Research Teams up with Qt Service Engineers.

Read more

Navico – Marine Navigation & Information System

Navico uses Qt for Lowrance HDS marine electronics range.

Read more

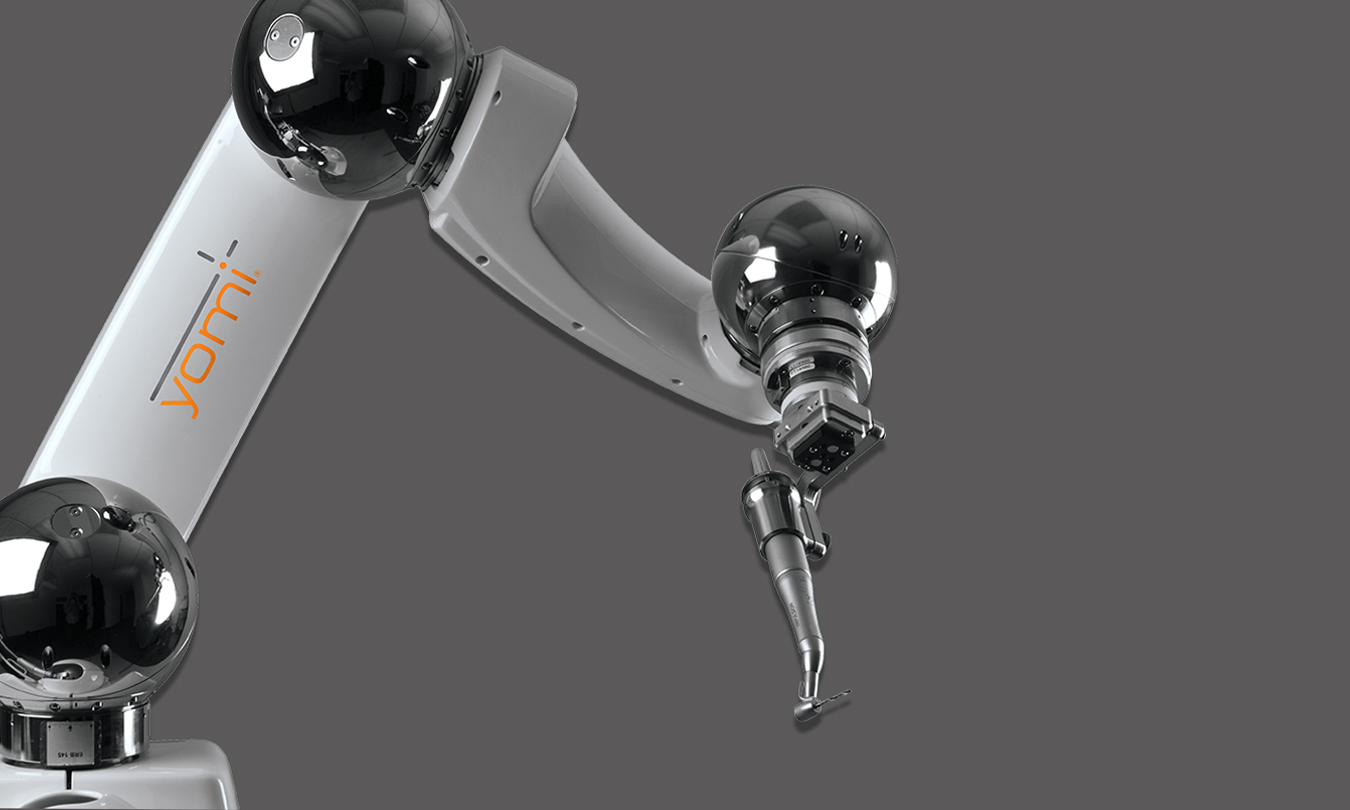

Neocis Dental Robots

Qt empowers Neocis, a dental robotics company, to modernize their UI and make their operation truly cross-platform.

Read more

Novatron Is Bringing Heavy Machinery Into the Digital Era

Read about how Novatron, a technology company focused on earthmoving automation, simplified their UI/UX operations with the help of Qt's framework.

Read more

Panasonic Avionics – Inflight Infotainment

Panasonic Avionics Inflight Entertainment used Qt to develop Inflight Entertainment systems experienced by over five million passengers every day.

Read more

Parker Hannifin – Parker Application Designer

Parker Hannifin has created a tool based on Qt allowing OEMs to consolidate a machine's UIs into one single display.

Read more

Produce Great Quality Work In Less Time With Zenreader

Qt's framework and components power Zenreader, a new tool for collecting and extracting knowledge efficiently whilst retaining the quality of work.

Read more

eyeMaps – Augmented Reality 3D Maps App

Start-up company, eyeMaps, built with Qt to quickly design an augmented reality 3D maps app for iOS & Android. Qt has great documentation & is...

Read more

Article: Scalable and Adaptable Inflight Entertainment System - Innov8Cabin Solutions

Scalable and adaptable inflight entertainment system. Witekio acted as the co-pilot of this new innovative inflight entertainment system - Innov8Cabin...

Read more

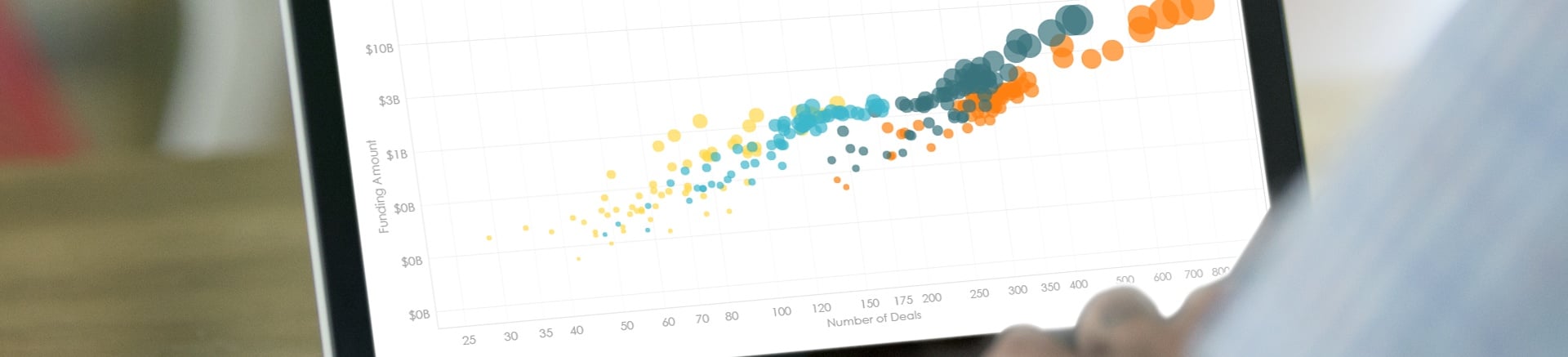

Tableau – Business Intelligence and Analytics

Using Qt, the business intelligence and analytics leader has changed the way people use data.

Read more

Ubuntu – Linux Distro

Ubuntu is a single, fully maintained OS that runs across a whole family of personal computing form factors and Qt is at the heart of the Ubuntu's UI f...

Read more

Ulstein – Ship Automation System

Read how Qt brings Ulstein’s daring & industry disruptive vision to reality.

Read more

Harness The Power of Algorithmic Trading with Volven

Qt's framework and components power Volven, a trading platform with sophisticated algorithms specially designed for the crypto market.

Read more

%20copy.jpg)